Steel Pipe With Cast Basalt Lining

Steel pipe with cast basalt lining is composed by lined with cast basalt pipe, outside steel pipe and cement mortar filling between the two layers.

It combines the advantages of cast basalt and steel pipe, wear resistance, corrosion resistance, anti-high-pressure, transportation and easy installation. Water transport in plant ash and metal mine tailings pipeline hydraulic conveyance system appling this product can life up to 30 years. Cast basalt lined steel pipe is divided into straight tube, elbow, tee, reducer pipe.

Cast basalt is a durable, resistant, and reliable and widely used manufacturing material being used in variant construction projects and industries. The linings made from cast basalt are strong and have long lasting effects. This is why most of the industries prefer using cast basalt linings in most of their manufacturing and processing operations.

Adopt centrifugal casting manufacturing cast basalt pipe reducer. Molten lava in the vacuum state is poured into the high-speed rotation the centrifuge. In fixed standard time to exit the centrifuge into the annealing furnace. Cast basalt pipes have an excellent performance of high abrasive and high corrosion resistance. Often in the form of cast basalt pipe reducer appeared in various operating conditions the pump outlet location.

As hydraulic or pneumatic conveying worn or corrosive wear resistance, corrosion resistant lining material pipe can effectively protect the pipe prolong the service life of pipelines.

The whole production process of cast basalt wear resistant materials are completely finished under the monitoring of internal control procedures for the safe and orderly.

Main Specification Of Cast blast lined pipe and fittings

| Cast Basalt Pipe DN (mm) | Standard Steel Pipe OD (mm) | Cast Basalt Thickness (mm) | Length |

| 80 | 159 | 25 | 4000 |

| 100 | 168 | 17.520 | 4000 6000 8000 |

| 125 | 195 | ||

| 150 | 219 | ||

| 175 | 245 | 6000 8000 10000 12000 | |

| 200 | 273 | ||

| 225 | 300 | ||

| 250 | 325 | ||

| 275 | 345 | ||

| 300 | 377 | ||

| 350 | 426 | ||

| 400 | 478 | 20 25 | |

| 450 | 529 | ||

| 500 | 600 | 25 | |

| 550 | 650 | ||

| 600 | 720 | 30 | 6000 |

| 650 | 770 | ||

| 700 | 820 | ||

| 750 | 870 | ||

| 800 | 920 |

Other specifications of cast steel pipe lined with basalt can be manufactured according to customer technical requirements. Suitable for large-diameter basalt lining steel pipes with a nominal diameter greater than 800mm. Generally, according to the running status of the pipeline, different cement is used to fix the basalt brick inside the finished steel pipe to complete the basalt lining steel pipe. Its advantages are good wear resistance, wide range of use, basically not limited by the size of the pipeline and low cost of pipeline installation.

Comparision Chart

Comparison of Ceramic lines with few other materials under standard conditions :

| Material | Thickness(mm) | Approx life ( Months ) |

| Mild Steel | 10 | 3-5 |

| Cast Iron | 20 | 6-8 |

| Ni-Hard | 20 | 12-14 |

| Cast Basalt | 30 | 20-25 |

| Ceramic | 10 | 35-40 |

Ceramic lined equipment and bends

Hard & Compact Smooth & Inner Withstands High-Abrasion & Corrosion In any of the process industries especially Sled and Cement corrosion and abrasion lead to significant downtime of the plant. Further, the useful life or the equipment itself may get impaired because of the high abrasive nature of the materials being used. Thus, ‘wear mechanism’ results in hut down, replacement, etc., which is costly, resulting in loss to tilt: tunic of millions of dollars.

Characteristics

- High resistance to all types of chemicals.

- High resistant to sliding abrasion.

- Non weld ability & smooth surface results ill easy How of materials.

- Can With stand and temperature up to 200 C.

- Smooth Surface and resistant to abrasion & corrosion.

Technical details:

- Friction Resistance: As more material is passed over Cast Basalt, it gets polished up thereby reducing friction further. Cast Basalt improves in service after getting polished. Wetting also improves its performance in practical applications.

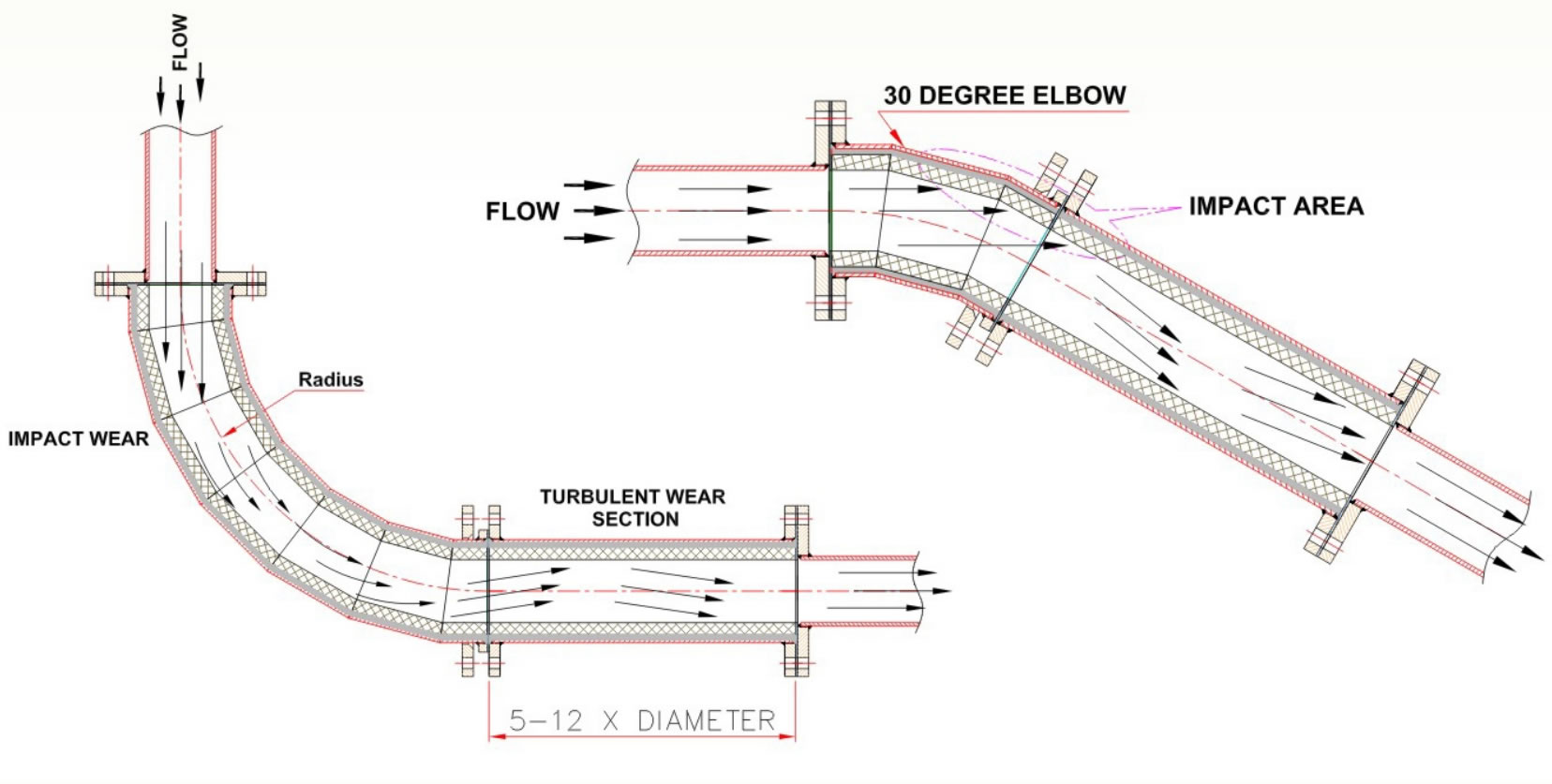

- Impact Resistance: Direct Impact Resistance at a perpendicular angle is low like all other ceramics, but it can be increased with proper installation by reducing the angle of impact. Cast Basalt can be used to mitigate sliding abrasion. Moreover, external impact strength of composite basalt pipe (enclosed in M.S. Shell) is always more than that of bare Ni-hard Pipe.

- Chemical Resistance: Cast Basalt is almost absolutely acid/alkali resistant (except Hydrofluoric Acid) and hence corrosion resistant.

- Weight and Sizes: Basalt Tiles are available in regular shape square of 200 x 200 x 30 mm thick, weighing approximately 90 kg/sq. m; whereas bends and pipes are lined using Basalt Cylinders of various standard sizes from 50NB up to 500NB.

- Temperature: Cast Basalt withstands temperature up to 450ºC.

- Life: Life of basalt-lined pipe is estimated to be 7 to 10 times that of Cast Iron, and 3 to 4 times that of Ni-hard Steel.

Why are cast basalt lined pipes so wear-resistant

Cast basalt pipe can be divided into straight pipe, elbow, three-way (four-way) pipe and variable diameter pipe, etc.

The cast basalt lined pipe has the characteristics of thoughtful structure, low water absorption, high compressive strength and good wear resistance. Except hot phosphoric acid, hydrofluoric acid and dissolved alkali above 30℃, it has good corrosion resistance to almost all inorganic acids, organic acids, alkalis, salts, water and organic solvents. The brittle material of cast stone has high hardness, and the problem of cast stone is that it is brittle and is not easily impacted by heavy objects.

Under the microscope, the cast stone can be seen interlaced with individual pyroxene spheres or feather-like crystallites of 0.05-0.1 mm. The thoughtfulness of this internal structure greatly improves the hardness of the cast stone, and its mohs hardness reaches 7~8. The greater the hardness of the material, the better the wear resistance. From the point of view of atomic and molecular structure, the combination of silicon and oxygen atoms of this silicate mineral is connected with each other by a strong force.

Individual cast basalt lined pipes have good wear resistance in blast furnace tank utilization, and meet application requirements in terms of wear resistance, but there are also brittleness of ceramic materials, which are easily broken during the process of falling ore. The construction of single-piece pasting is incomplete, and signs of aging will appear after a long time of pasting. The wear-resistant material not only has good wear resistance in the use of blast furnace tanks, but also meets the application requirements in terms of wear resistance, and has a mortar material, which is tough and will not be smashed in the process of falling ore. Good performance, combined with cement, not limited by time and so on. The wear resistance of cast basalt lined pipes is also the reason for their widespread use.

The connection of cast basalt line steel pipe

Cast blast lined pipe and fittings can connect with flange, quick assembly joints and welding.

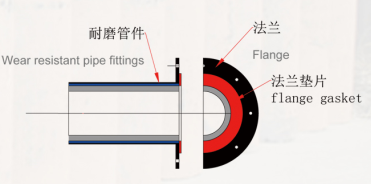

Flange connection

Flange connection is one kind of common pipeline installation connections. By two pieces of flanges, pipeline, valve, equipments are connected and it forms a tight piping system. When pipeline pressure is larger, flange connection is priority selection. Flanges have lots of different sizes. Flange size is determined according to pipeline normal diameter and pipeline operation pressure.

The parameters of the outside steel pipe will be decided according to the working pressure of the system. The connection of the pipes and fitting will be of flange connections, easy—flexible joint connection or by welding.

By two pieces of flanges,pipeline,valve,equipments are connected and it forms a tight piping system. When pipeline pressure is larger, flange connection is priority secection. Flanges have lots of differents sizes.

Flange size is determined according to pipeline normal diameter and pipeline operation pressure.

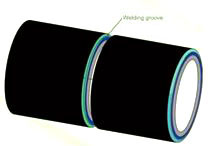

Welding & Beveled end

It suits short distance pipeline system without maintenance. It is one kind of common installation connections. It requires installation personnel higher welding ability. It also restricts by welding site, distance, welding positions. Welding connections is inconvenient in later maintenance.

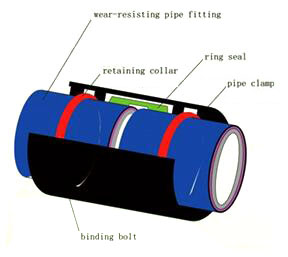

Easy-Flexible joint connection

It is one of high efficient and rapid installation connection. I t has the below characteristic: easily install and disassemble, fast installation, temperature adjustable compensation function, saving the necessary expansion in long pipeline. Easy-flexible joint also has angle compensation characteristic. At smaller angle turning points, easy-flexible joint can be instead of bends and adjust angle.

Application area of cast basalt products

Cast basalt can be used for the lining of pipework, chutes, bunkers, cyclones, and hoppers. It has become the global standard in areas such as ash slurry pipework, often used at fossil-fuel power stations. It is an all-round cost-effective and adaptable lining material that extends the life of equipment in pipe or tile form where affected by erosion.

Cast basalt is well-proven in a variety of industries as a cost-effective, long-lasting lining material used to extend the operating life of equipment manufactured or lined with lower-wearing materials such as steel, cast iron, rubber, and polyurethane.

Cast basalt lined steel pipe, as both a wear—resistant and corrosion—resistant materials, the transport properties of wear or corrosion of materials, after thirty years of practical verification, cast basalt lined steel pipe can be well done.

Cast basalt is also used in cement plants for making air separators, chain conveyor, silica hoppers, nozzles, coal hoppers, cement hoppers, cyclones, raw mill ducts, chutes, thick slurry lines, mixers, grate cooler housing, coal ventury etc.

- Tailings pipeline

- concentrate pipeline

- pipeline of transporting ore

- pipe of transporting ash and residue in electric power station

- pipe for transporting coal—water

- pipe of sending sand by wind power

- The concentration of slurry chute

- edge—milling machine

- disk feeder

- slurry chutes

- blast flush fines chute

- blast furnace slag ditch

- raw ore chute

- funnels of autogenously mill

- classification return mines chute

- overflow launder

- coke—conveying chute

- saturator

- acid separator

- cyclone separator

- sand mixed machine

- punch mine ditch in mining industry

- storage tank mine blast, coke funnel

- all kinds of chutes, funnels, storage bin andso on.

- load and unload material chute in fire—resistant industry

- centrifugal concentrator punch mine launder

Cast basalt composite pipes used for years

- hydro cyclone

- precipitator

- pickling tank

- slag conveyor

- mixing machine downhill plate

- conveying equipments need wear protection

Design aspects

The bend radius should be minimum 3 times of the nominal bore. At discharge end of each bend, cast basalt lined straight pipe of length 5 to 12 times the nominal bore must be used.